Description

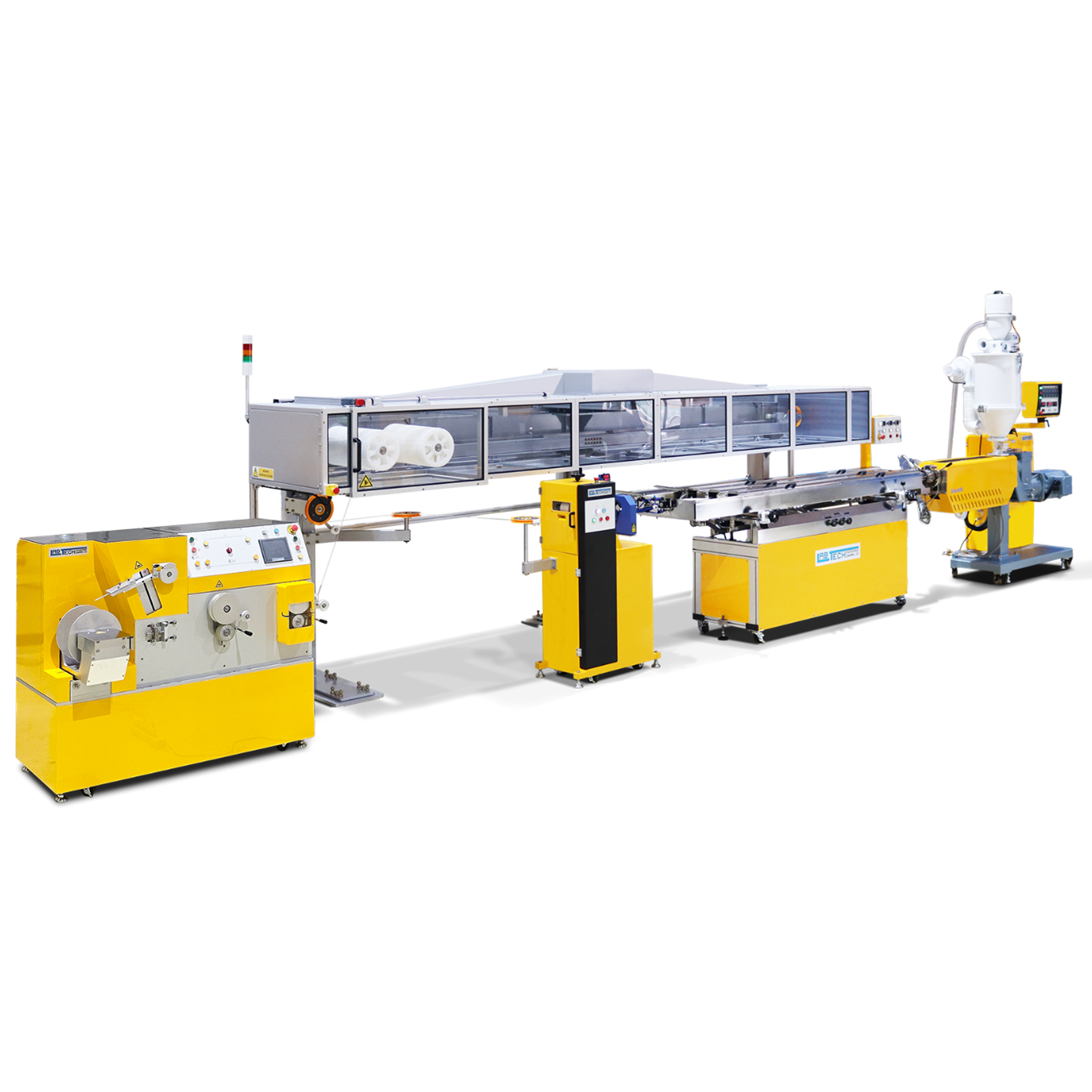

Our newly redesigned High-Speed 3D Filament Extrusion Line. Built with advanced components, this line boasts a maximum speed of up to 130 m/min, accommodating various resin types including PLA, PETG, TPU, ABS, PA, TPE, and carbon fiber composite. With a compact design spanning just 10.5 meters in total length, it’s the epitome of space-saving productivity.

Key Features:

- Scientific 40 mm Single-Screw Extruder Type LE40-30/C:

- Modern “One Pillar” design for space efficiency.

- Equipped with high-grade nitride steel screw and barrel.

- Variable screw speed from 0 to 200 RPM for precise control.

- Four heating zones with efficient air-cooling for rapid temperature adjustments.

- Digital programmable temperature controllers ensure precise heat control.

- Optional equipment includes pressure transducer and melt temperature sensor for enhanced monitoring.

- Optional Equipment for Enhanced Performance:

- Hopper dryer recommended for continuous production runs.

- Automatic fillers for the hopper ensure smooth material flow.

- Closed-loop system extruder control for precise regulation of resin flow.

- 3D Filament Dies:

- Horizontal and vertical dies cater to various resin types and filament sizes.

- Changeable die plates ensure compatibility with different filament diameters.

- Triple Chamber Water Bath Type LTCW-150:

- Zigzag design for gradual cooling, preventing filament distortion.

- Equipped with hinged steel covers for contamination prevention.

- Optional three-axial handwheel allows for easy adjustment.

- High-Speed Roller Haul-Off Unit Type LCAT-130:

- Adjustable pulling pressure for consistent filament production.

- Optional dual-axis laser diameter measuring gauge for precise diameter control.

- Horizontal Filament Accumulator Type LHFA-200:

- Doubled filament capacity compared to previous models.

- Synchronized with winder for uninterrupted operation during spool changeover.

- High-Speed Single-Station Wind-Up Unit Type LWU-130:

- Pneumatic two-side clamp plate system for secure spool holding.

- Spring-loaded nip roll for consistent filament tension.

- Integrated safety features ensure operator protection.

TECHNICAL DATA FOR 3D FILAMENT EXTRUSION LINE

| 40 MM SINGLE-SCREW EXTRUDER TYPE LE40-30/C | ||||

| Screw Diameter | 40 mm | |||

| Standard Screw L/D Ratio (others on request) | 30 | |||

| Motor Power | 15 kW | |||

| Motor Power for Vector Drive | 22 kW | |||

| Screw Speed Range | 0 to 200 RPM | |||

| Number of Heating Zones on the Barrel | 4 | |||

| Maximum Barrel Temperature | 300°C (optional 400°C and 450°C) | |||

| Temperature Controllers on Panel | 4+2 for Die Adaptor | |||

| Forced Air Cooling on all Heating Zones | YES | |||

| Total Heating Power | 8.2 kW | |||

| Maximum Output of Extruder (LDPE) | 45 kg/hr | |||

| TRIPLE CHAMBER WATER BATH TYPE LTCW-150 | ||||

| Water Bath Material | Stainless Steel | |||

| Water Bath Length | 3.5 meters | |||

| Chamber Section Length | 3.0 meters | |||

| Water Bath Capacity | 58 L per Chamber Section | |||

| ROLLER HAUL-OFF UNIT TYPE LCAT-130 | ||||

| Rubber Roller Diameter | 100 mm | |||

| Rubber Roller Width | 80 mm | |||

| Maximum Operating Speed | 130 m/min | |||

| SINGLE-STATION WIND-UP UNIT TYPE LWU-130 | ||||

| Spool Type | RS 200 | RS 300 (Option) | RS 350 (Option) | |

| Spool Diameter | 200 mm | 300 mm | 350 mm | |

| Spool Width | 45 mm | 65 mm | 90 mm | 90 mm |

| Motor Drive | 0.75 kW | |||

| Maximum Operating Speed | 130 m/min | |||

NOTE: Filament Output (kg/hr) depends on the Material, Filament Diameter (mm) and Line Speed (m/min), e.g., for PLA/ABS, Ø1.75 mm at 130 m/min: 19/23 kg/hr and Ø2.85 mm at 60 m/min: 23/28 kg/hr.