Our newly revamped High-Speed 3D Filament Extrusion Line boasts cutting-edge components that enable a maximum line speed of 130 m/min, accommodating a wide range of resin types including PLA, PETG, TPU, ABS, PA, TPE, and carbon fiber composite. With filament diameters of 1.75 mm and 2.85 mm (custom diameters available on request), it caters to all printer brands, ensuring compatibility across the board.

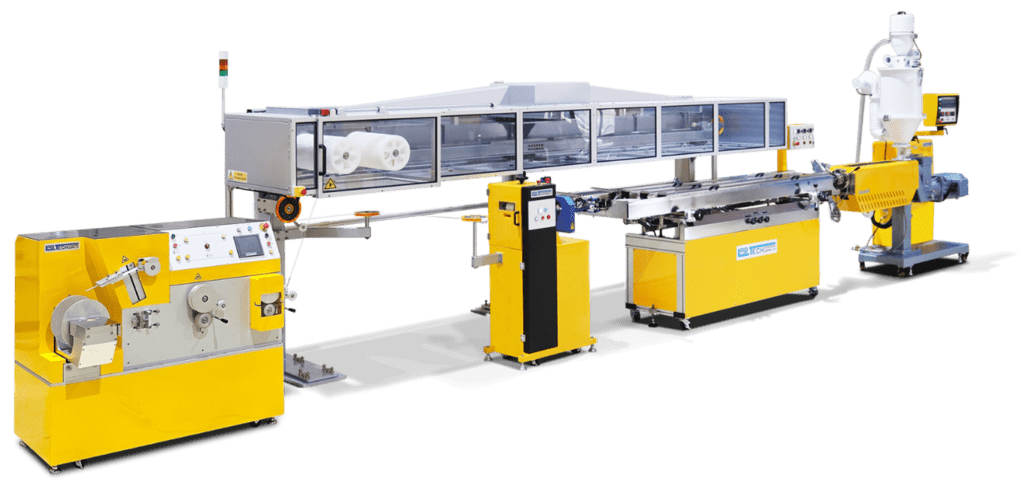

Designed for seamless operation, this extrusion line is engineered to run continuously, delivering optimal returns on your investment. At its core is our 40 mm Single-Screw Extruder, which can be optionally equipped with a drying hopper and autoload system. Despite its high performance, the line maintains a compact footprint, measuring just 10.5 meters in total length.

A standout feature of our extrusion line is its innovative design for heating and cooling, achieved through a shortened heating and cooling bath featuring three independent water chambers. This design allows the filament to pass through in a zigzag pattern, ensuring precise calibration, heating, and cooling.

Safety is paramount, and our extrusion line meets CE safety regulations as well as global safety standards. The horizontal filament accumulator can store up to 200 meters of filament, providing ample time for operators to change spools on the winder without interruption.

Finally, our extrusion line is equipped with a state-of-the-art single-station filament winder featuring a new lay-on system. This system ensures the filament is evenly wound onto the spool, resulting in high-quality, consistent output.

Experience unmatched efficiency, precision, and safety with our High-Speed 3D Filament Extrusion Line – the ultimate solution for filament production.

TECHNICAL DATA FOR 3D FILAMENT EXTRUSION LINE

40 MM SINGLE-SCREW EXTRUDER TYPE LE40-30/C |

Screw Diameter | 40 mm |

Standard Screw L/D Ratio (others on request) | 30 |

Motor Power | 15 kW |

Motor Power for Vector Drive | 22 kW |

Screw Speed Range | 0 to 200 RPM |

Number of Heating Zones on the Barrel | 4 |

Maximum Barrel Temperature | 300°C (optional 400°C and 450°C) |

Temperature Controllers on Panel | 4+2 for Die Adaptor |

Forced Air Cooling on all Heating Zones | YES |

Total Heating Power | 8.2 kW |

Maximum Output of Extruder (LDPE) | 45 kg/hr |

TRIPLE CHAMBER WATER BATH TYPE LTCW-150 |

Water Bath Material | Stainless Steel |

Water Bath Length | 3.5 meters |

Chamber Section Length | 3.0 meters |

Water Bath Capacity | 58 L per Chamber Section |

ROLLER HAUL-OFF UNIT TYPE LCAT-130 |

Rubber Roller Diameter | 100 mm |

Rubber Roller Width | 80 mm |

Maximum Operating Speed | 130 m/min |

SINGLE-STATION WIND-UP UNIT TYPE LWU-130 |

Spool Type | RS 200 | RS 300 (Option) | RS 350 (Option) |

Spool Diameter | 200 mm | 300 mm | 350 mm |

Spool Width | 45 mm | 65 mm | 90 mm | 90 mm |

Motor Drive | 0.75 kW |

Maximum Operating Speed | 130 m/min |

NOTE: Filament Output (kg/hr) depends on the Material, Filament Diameter (mm) and Line Speed (m/min), e.g., for PLA/ABS, Ø1.75 mm at 130 m/min: 19/23 kg/hr and Ø2.85 mm at 60 m/min: 23/28 kg/hr.