Description

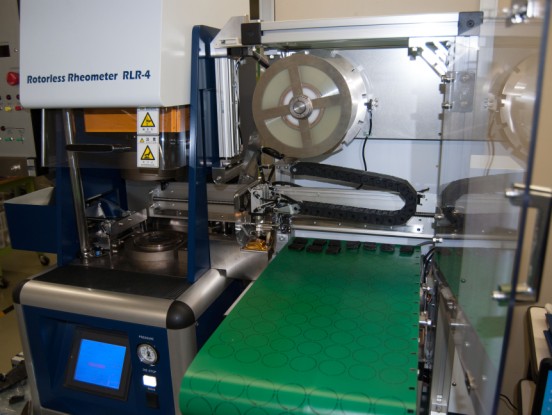

The Rotorless Rheometer model RLR-4 measures vulcanizing characteristics of rubber with ease and simplicity at high accuracy.

It allows labor saving in conducting test by installing the pin type automatic sample loading/unloading device of high reliability and high reputation and data processing unit as option.

Moreover, it allows you to determine more physical characteristics of rubber by installing the optional foaming pressure measuring function and tanδ measuring function.

FEATURES

- LCD touch screen control panel

- LCD touch screen is used to assure easy operation. Curing curve etc. can be monitored on the screen in real time and up to 5 curves can be displayed overlapped on the screen. (Stand-alone operation without personal computer is possible)

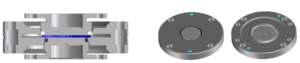

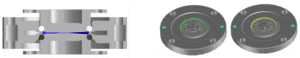

- Flat-plate-die & Biconical-die is selectable

- Flat-plate-die (ISO 6502 / JIS K 6300-2)…Standard

- Biconical-die (ISO 6502 / ASTM D 5289, ISO 13145)…Option

- Flat-plate-die (ISO 6502 / JIS K 6300-2)…Standard

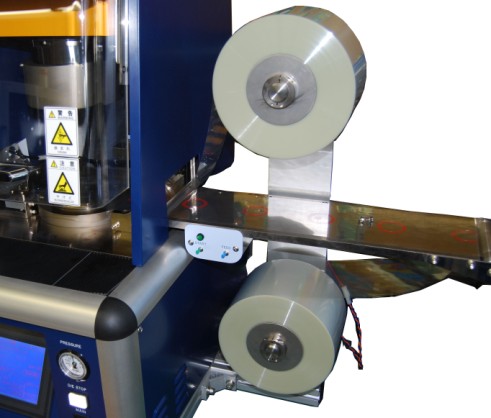

- Automatic Torque Calibration

- Calibration can be automatically performed by means of the built in actual weight by once touch from the control panel.

Built-in weight for automatic calibration

- Calibration can be automatically performed by means of the built in actual weight by once touch from the control panel.

- Testing Operation

- Angle of oscillation can be arbitrarily set within ±0.1°~±2.00º range in 0.01° steps.

- Number of oscillations can be arbitrarily set within 50cpm ~ 150cpm range in 1cpm steps.

- Data Output

- For output of measured data you can select mini printer output (option) or data processing unit (option) with control function.

- Safety Devices

- For overheat protection, a temperature monitoring circuit independent from the test temperature control circuit is installed in the upper and lower heating platens.

- By closing the wind protection door the heating platen comes down and test starts.

- Measuring Function Options

- Programmed heating function can be added as option that can simulate the foaming pressure measuring function capable of measuring the relation between curing and forming, tanδmeasuring function capable of measuring viscoelastic characteristics and multistage curing, etc.

SPECIFICATIONS

| Model | RLR-4 |

| Test chamber | Rotorless, Non-friction sealed type

|

| Pressure applying system | Pneumatic cylinder (Non-lubrication type) |

| Heating system | Electric heating |

| Temperature range | Room temperature + 20°C to 230°C

Accuracy ±0.3°C Resolution 0.1°C |

| Oscillation frequency | 50cpm (0.83Hz) to 150cpm (2.5Hz)

(Variable in 1cpm steps) Note: cpm=Cycles per minute |

| Oscillation amplitude | ±0.10 to ±2.00° (Variable in 0.01°steps) |

| Drive motor | Stepper motor |

| Torque detector | Strain gauge type load cell |

| Torque range | 100dN.m auto range, minimum unit 0.01dN.m (Max. 200dN.m) |

| Test time setting | 3 to 960min in 10 steps |

| Torque calibration | Auto span function using built-in weight |

| Torque auto zero | Auto zero function before starting test |

| Safety devices |

|

| Communication | RS-232C |

| Control panel | 5” LCD touch screen |

| Operation menu |

|

| Languages |

|

| Power requirement | Single-phase, AC200 to 230V, 50Hz or 60Hz, 2.4kVA |

| Compressed air requirement | 0.45MPa |

| Dimensions | W430 x D600 x H1120mm |

| Weight | Approx. 145kg |

| Related standards | ISO 6502

ISO 13145 (Option) JIS K 6300-2 ASTM D5289 (Option) |

Related standards

ISO 6502

JIS K 6300-2

ASTM D5289 (Option)

ISO 13145 (Option)