Description

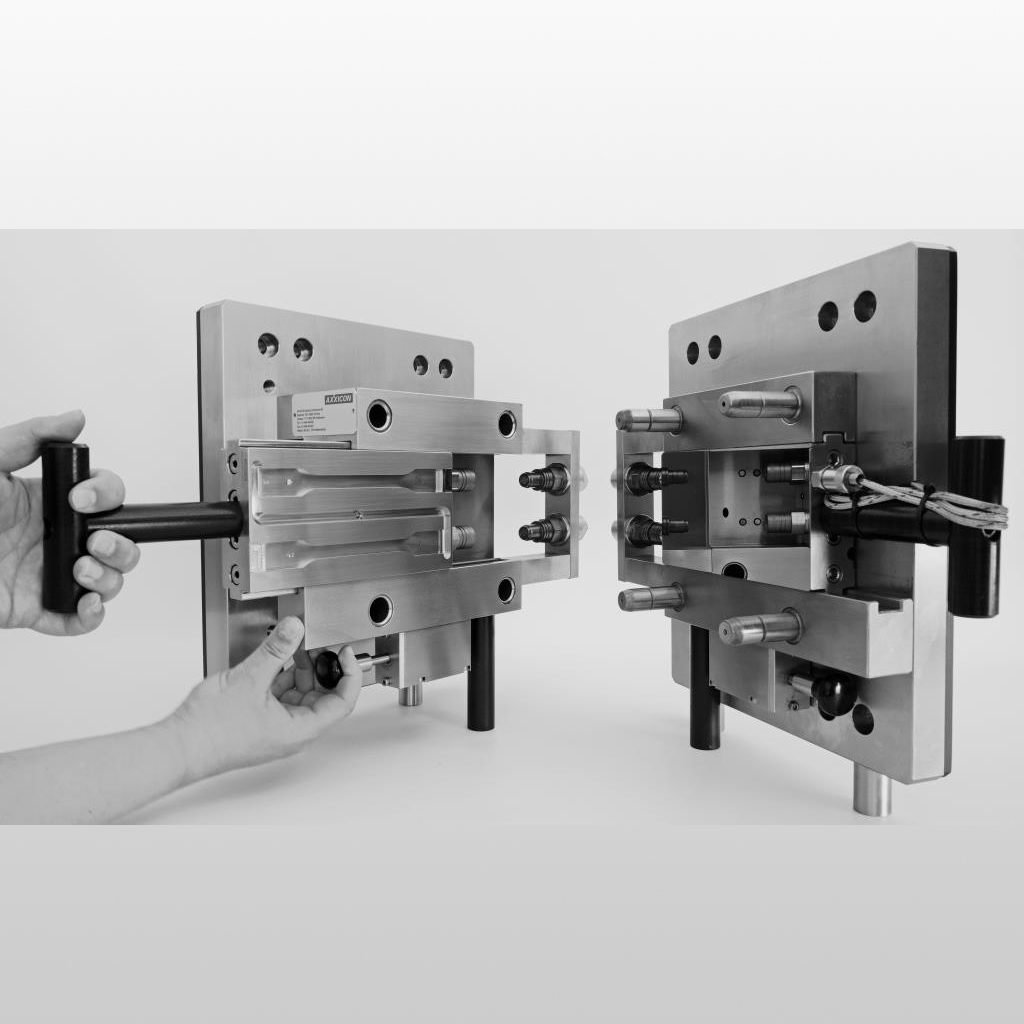

This is a dedicated jig for making cuts of specified dimensions in the prepared test piece.

Unlike the conventional type, the cutting edge slides in an arc, making it possible to reliably cut even low-hardness materials such as silicone rubber as specified.

| Model SDSC-1200NJ | JIS K6252, ISO-34 Crescent type only Depth of cut 1.00±0.2mm |

| ModelSDSC-1200J | Depth of cut 0.50±0.08 mm for JIS K6301 A type |

| ModelSDSC-1200AS | Depth of cut 0.50±0.05mm for ASTM D624 Type B |

| Method of operation | ① Set the workpiece in the cavity (upper part of the photo) and cover it. (2) Simply press down the cavity part lightly to complete the work. |

| airframe dimensions | (Approx.) (W) 130 x (D) 150 x (H) 220mm |

Ⅰ Comparison of notches between conventional jigs and devised jigs using images

Hardness: JIS-A 62/Tensile strength: 5.49MPa/Elongation: 240%

Left: Conventional jig/Right: Invented jig

Hardness: JIS-A 14/Tensile strength: 4.31MPa/Elongation: 760%

Left: Conventional jig/Right: Invented jig

Ⅱ Comparison of conventional jigs and devised jigs based on data

Table 1 Comparison of results with silicone rubber

| Conventional jig (0.5mm) | Devised jig (0.5mm) | Devised jig (1.0mm) | ||

| Average value of cutting length (mm) | shallow | 0.442 | 0.488 | 0.986 |

| deep | 0.688 | 0.545 | 1.055 | |

| Average *1 | 0.565 | 0.517 | 1.020 | |

| depth of cut | 0.246 | 0.057 | 0.069 | |

| CV value of cut (%) | shallow | 21.4 | 5.5 | 7.8 |

| deep | 24.3 | 6.9 | 10.0 | |

| Average *2 | 12.6 | 4.9 | 8.7 | |

| CV value of tear strength (%) | 2.7 | 2.1 | 1.7 | |

*0 Reference value [Hardness JIS-A 60 Tensile strength 7.94MPa Elongation 290%]

*1 Average is calculated by (shallow + deep) / 2

*2 Calculated based on the average value of each [*1]

Table 2 Comparison of various rubbers

| kinds | Reference physical properties | Cutting length (mm) *1 | CV value of cut (%) *1 | ||||

| Hardness | Tensile strength | stretch | Conventional jig (0.5mm) | Devised jig (0.5mm) | Conventional jig (0.5mm) | Devised jig (0.5mm) | |

| A. | JIS-A14 | 4.31 MPa | 760% | 0.867 | 0.475 | 23.3 | 19.0 |

| B. | JIS-A 30 | 4.70 MPa | 340% | 1.058 | 0.548 | 26.6 | 6.8 |

| C. | JIS-A38 | 7.06 MPa | 350% | 1.018 | 0.510 | 9.2 | 3.9 |

| D. | JIS-A60 | 7.84 MPa | 290% | 0.565 | 0.517 | 12.6 | 5.0 |

| E. | JIS-A62 | 5.49 MPa | 240% | 0.492 | 0.475 | 2.9 | 0.0 |

*1 Cut length and CV value of cut are calculated by average of cut (average of cut on front/back of workpiece [shallow + deep]/2)

| kinds | Reference physical properties | Cutting length (mm) *1 | CV value of cut (%) *1 | ||||

| Hardness | Tensile strength | stretch | Conventional jig (0.5mm) | Devised jig (0.5mm) | Conventional jig (0.5mm) | Devised jig (0.5mm) | |

| for rolls | JIS-A1 | 0.98MPa | 450% | No notch | 0.625 | No notch | 0.0 |

| for rolls | JIS-A 10 | 1.27 MPa | 300% | 0.900 | 0.592 | 7.4 | 6.5 |

| rubber contact | JIS-A13 | 4.12 MPa | 740% | 1.317 | 0.625 | 17.6 | 14.4 |

| rubber contact | JIS-A14 | 4.31 MPa | 760% | 0.867 | 0.475 | 23.3 | 19.0 |

| for molding | JIS-A 30 | 4.70 MPa | 340% | 1.058 | 0.548 | 26.6 | 6.8 |

| nipple | JIS-A 35 | 10.78 MPa | 890% | 0.485 | 0.586 | 37.8 | 7.1 |

| for molding | JIS-A36 | 11.76 MPa | 900% | 0.858 | 0.617 | 13.1 | 2.3 |

| rubber contact | JIS-A38 | 7.06 MPa | 350% | 1.018 | 0.510 | 9.2 | 3.9 |

| for insulation | JIS-A60 | 7.84 MPa | 290% | 0.565 | 0.517 | 12.6 | 5.0 |

| for molding | JIS-A62 | 5.49 MPa | 240% | 0.492 | 0.475 | 2.9 | 0.0 |

*1 Cut length and CV value of cut are calculated by average of cut (average of cut on front/back of workpiece [shallow + deep]/2)

| Variation in depth of cut for all products | |||

| CV value (%) manual | CV value (%) machine (0.5 mm) | CV value (%) machine (1.0 mm) | |

| shallow | 53.0 | 10.4 | 6.4 |

| deep | 33.0 | 11.9 | 8.1 |

| average | 37.3 | 8.5 | 6.7 |

| Average depth of cut of all products (mm) | |||

| manual | Machine (0.5mm) | Mechanical (1.0mm) | |

| shallow | 0.640 | 0.495 | 1.002 |

| deep | 0.966 | 0.575 | 1.098 |

| average | 0.803 | 0.535 | 1.050 |

| front-rear difference | 0.326 | 0.080 | 0.096 |